Xinxiang Hundred Percent Electrical And Mechanical Co.,

Ltd.(BEFANBY) is a professional international material handling

equipment company integrating R&D, design, production and

sales. It has a modern management team, technical team and

production technician team.The company was established in September

2003 and is located in Xinxiang, Henan. BEFANBY can not only

provide transfer cart quotations, but also provide you with

satisfactory handling solutions.

BEFANBY has an annual production capacity of more than 1,500 sets

material handling equipment, which can carry 1-1,500 tons of

workpieces. With more than 20 years of experience in the design of

electric transfer carts, it already has the unique advantages and

mature technology of designing and producing heavy-duty AGV and

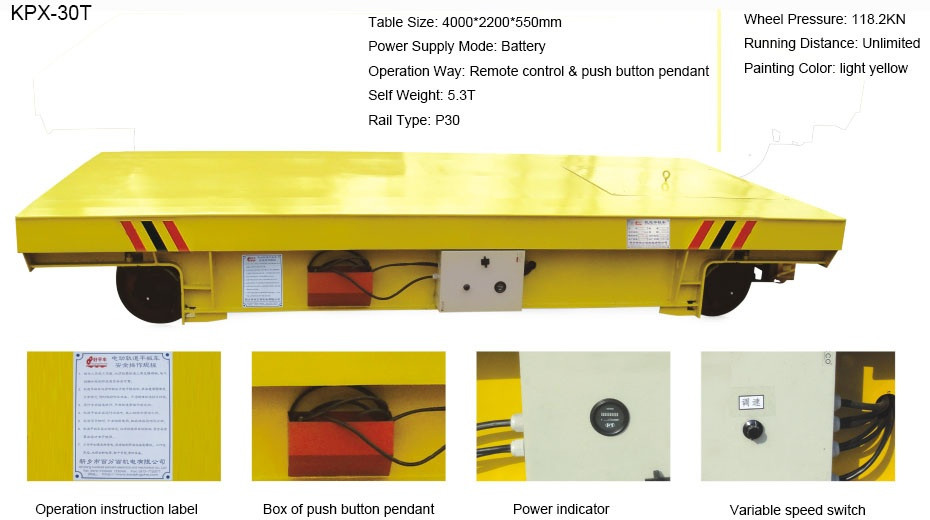

RGV. The main products include AGV (heavy duty), RGV, KPD

low-voltage rail type, KPX battery type, KPT towing cable type, KPJ

cable reel type, KPC sliding contact line type, BWP trackless type,

KP unpowered type, BZP turntable , BWT flatbed trailer and other

eleven series. Including conveying, turning, coil, ladle, painting

room, sandblasting room, ferry, hydraulic lifting, traction,

explosion-proof and high temperature resistant, monorail, generator

power, railway maintenance cart, railway and road tractor,

locomotive turntable and other hundreds of handling equipment and a

variety of transfer cart accessories. Among them, the

explosion-proof battery electric transfer cart has obtained the

national explosion-proof product certification, number:

CNV21.0215X.

BEFANBY products are sold to all over the world, such as United

States, Canada, Mexico, Germany, Chile, Russia, Saudi Arabia, the

United Arab Emirates, Thailand, Singapore, Indonesia, Malaysia,

Australia, South Korea and other more than 90 countries and

regions.

1. Material handing equipment

- AGV Automatic Guided Vehicle; RGV Rail Guided Vehicle

- Rail transfer cart, motorized transfer trolley, coil transfer cart

- Ladle transfer car, turning transfer cart

- Hydraulic lifting transfer cart

- Customized Transfer Cart

- Electric turntable

- Trackless transfer car

- Train tractor

- Flatbed Trailer

- Winch

- Railway wheel

- Steel rails

2. Product line, assembly line and workshop, warehouse handling

solution provide

Painting line

Mold handing in workshop

Steel coil, ladle, steel scrap handling on production line

Workshop crossing rail layout handling solution

90 Degree turning rail path handling solution

Arc rail factory handling routie handling

Our Marketing Concept:

Attentively Manufacturng; Keeping on improving and elaborately

serving to make our customers satisified.

Manufacturing

Manufacturing